► Description

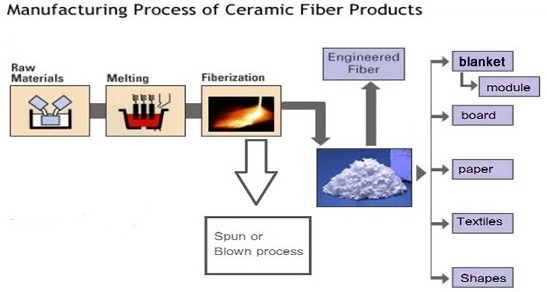

Sunrise ceramic fiber blanket series products through the selection of high-quality high purity ceramic bulk fiber , using resistance furnace melting, continuous spinning into fiber, cotton collection, double-sided needling, high temperature setting, horizontal and vertical cutting, rolling, made of light thermal insulation refractory.The advanced production technology makes the fiber layer interwoven evenly, the slag ball content is low, the lamination resistance and tensile strength are good, the flexibility is excellent, the wind erosion resistance is excellent.Ensure that the fiber blanket in high and low temperature working conditions can maintain good performance and stability.Widely used in industrial furnace wall lining, back lining insulation, high temperature pipe insulation, electrical components heat insulation fire proof, ceramic fiber module raw materials.

►Application

1. Heat insulation lining walls of furnaces, boilers and glass furnaces for aerospace, non-ferrous metal smelting, and petrochemical industry,heat insulation of furnace doors and roof;

2. Furnace lining thermal insulation;

3. Wall lining of thermal insulation equipment and heating equipment for electric boilers, gas turbines and nuclear power plants in chemical industry;

4. High temperature pipe insulation, flue lining;

5. Electrical components heat and fire insulation, high temperature insulation;

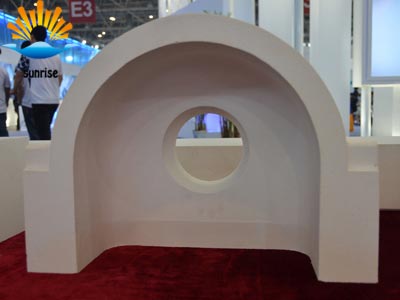

6. High temperature gasket, ceramic fiber module raw materials;

7. Fire prevention and heat insulation in ships, fire prevention and heat insulation in high-rise buildings;

8. Auto insulation and silencing components;

9. High temperature filter material.

► Characteristics

♦ Low thermal conductivity, low thermal capacity.

♦ Excellent chemical stability (except hydrofluoric acid and strong base).

♦ Excellent thermal stability and thermal shock resistance.

♦ Excellent tensile strength.

♦ Excellent heat insulation, fire resistance and sound absorption.

► Why us

Sunrise can offer customer excellent service relating to the production line of the float glass, which includes the design and advisory of the furnace and the tin bath, the matching of the materials and its construction. The products made by our company have been use in more than 80 production lines of float glass and production line of glass products both at home and abroad. We conscientiously observes the government's line, policy, laws and regulations, follows the international trade practice, adheres to the principle of equality and mutual benefit, complies with contract and keeps the promise. BWTC upholds the principle of "combining industry with trade", "technology with trade" and "export with import", to serve its customers at home and abroad sincerely!

Type |

Common1100 | Standard1260 | HA1300 | LZ1350 | HZ1430 | Bio-Fiber1100 | |

Operating Temperature |

950 | 1100 | 1200 | 1250 | 1350 | 1000 | |

|

Density kg/m3 |

96/128/160 | ||||||

Coefficient of thermal conductivity W/(m.k) |

≤0.153 | ||||||

Shot Content Φ ≥ 0.212mm % |

≤15 | ||||||

Tensile strength (Mpa) |

≥ |

||||||

Linear shrinkage on Heating (%) |

950℃*24h ≤-3 |

1100℃*24h ≤-3 |

1200℃*24h ≤-3 |

1250℃ | 1350℃*24h ≤-3 |

1000℃*24h ≤-3 |

|

Chemical Position |

|||||||

Al2O3 |

≥40 | 44-47 | 51-53 | 43-45 | ≥34 | <1.0 | |

Al2O3+SiO2 |

≥95 | ≥98 | ≥99 | 90 | * | SiO2 61-67 | |

Al2O3+SiO2 +ZrO2 |

* | * | * | * | ≥99 | CaO 27-33 | |

ZrO2 |

* | * | * | 5-7 | ≥15 | MgO 2.5-7 | |

Fe2O3 |

<0.6 | <0.5 | <0.3 | <0.2 | <0.2 | <0.6 | |

Na2O+K2O |

≤0.3 | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | * | |

| Common Size(mm) |

7200*610/1220*20/25; 5000*610/1220*30; 4500*610/1220*40; 3600*610/1220*50; Can customized |

||||||

| Package | Woven bags or cartons |

||||||

Factory strength »