► Product Description:

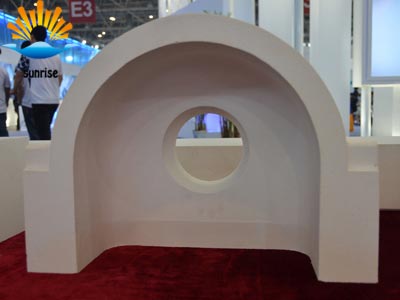

Sunrise inorganic ceramic fiber edition adopts high-purity ceramic fiber cotton as raw material, which is formed in one body by advanced technology, without secondary calcination and without organic matter.The new inorganic ceramic fiberboard has high strength and is smokeless and tasteless after being exposed to open fire, high temperature and high heat.Accurate size, low thermal conductivity, low slag ball content, minimal thermal shrinkage.Can be made according to the requirements of special-shaped pieces, ovens, wall hanging furnace and other ideal environmental protection insulation materials.

► Application:

♦ Heat insulation and heat preservation for high temperature and high heat equipment;

♦ Thermal insulation for industrial kilns

♦ Wall hanging stove, electric stove, oven, home appliances heat insulation

► Characteristic:

♦ Low shot content;

♦ No organic matter: direct contact with flame, high temperature and heat radiation;

♦ One time one-piece forming,accurate size.

♦ Extremely low thermal conductivity: only half that of traditional ceramic fibreboard;

♦ Heat shrinkable, no deformation at high temperature, cutting and drilling, convenient construction.

♦ High compressive strength: the strength does not change after high temperature sintering;

♦ Energy saving and environmental protection: high temperature, smokeless, tasteless and in line with environmental protection requirements.

|

Product name |

1260 Inorganic Ceramic Fiber Board |

|

Operating Temperature(℃) |

1100 |

|

Density kg/m3 |

280-500 |

|

Coefficient of thermal conductivity W/(m.k) |

0.09(900℃) |

|

Cold Crushing Strength(Mpa) |

0.14 |

|

Compresion strength after calcination(900℃*12h) |

0.16 |

|

Heating Permanent Change Line(900℃*12h)% |

-0.7 |

|

Size |

1000*600*3-50mm; 1200*500*3-50mm; 1200*1000*3-50mm, Other size can customized |

|

Package |

Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. |

Factory strength »