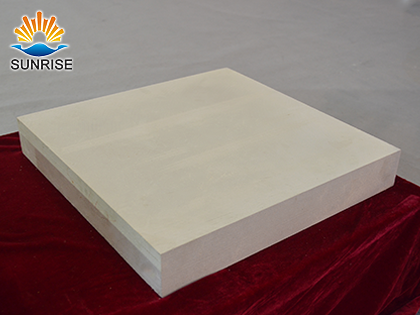

►Fused cast high zirconia bricks description

The series of TY-Z are fused cast high zirconia refractories which are specially designed refractory for glass furnace application. The crystalline texture consists of baddeleyite and with the characteristics of excellent high temperature & corrosion resistance, low blister and stoning potential. These advantages can prevent liquid glass from pollution effectively. wide application in glass industry,ceramic fiber industry and construction field,etc.

►Specification

--excellent high temperature & corrosion resistance

--low blister and stoning potential

--high purity raw materials

► Application field

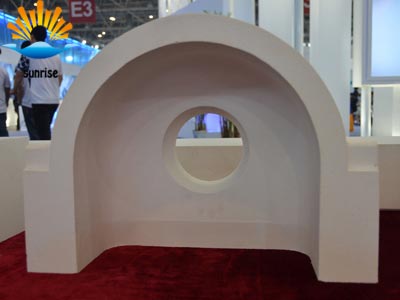

--Fused cast high zirconia brick has wide application in a wide range of super high temperature furnaces and kilns in military industry,science research, high melting point Metallurgical, laser crystal and electronic,etc.

--For high quality and special glass furnaces such as TV glass, Borosilicate glass, Alumina silicate glass, Halogen lighting glass, Opal glass and Fiber glass.

--TY-Z mainly consists of TY-Z88-WS and TY-Z95-WS, and are used in sidewall, throat cover, throat support, electrode block, dam block parts.

| Item | TY-Z88-WS | TY-Z95-WS | ||

| Chemical Composition % | ZrO2 | ≥ | 89.00 | 93.60 |

| SiO2 | ≤ | 9.00 | 5.30 | |

| Al2O3 | ≤ | 1.00 | 1.00 | |

| Na2O | ≤ | 0.05 | 0.51 | |

| Others | ≤ | 1.60 | 1.0 | |

| Mineral Composition % | Baddeleyite | Typical | 89 | 94 |

| Glass Phase | 11 | 6 | ||

| Physical Properties | Cold Crushing Strength (MPa) | ≥ | 400 | 400 |

| Bulk Density (g/cm³) | Typical | 5.10 | 5.30 | |

| Liner Thermal Expansion (%) | 1000℃ | 0.65 | 0.70 | |

| 1500℃ | 0.10 | 0.30 | ||

Factory strength »