Sunrise Refractory Deep Analysis of Fused Refractory

2019-12-24

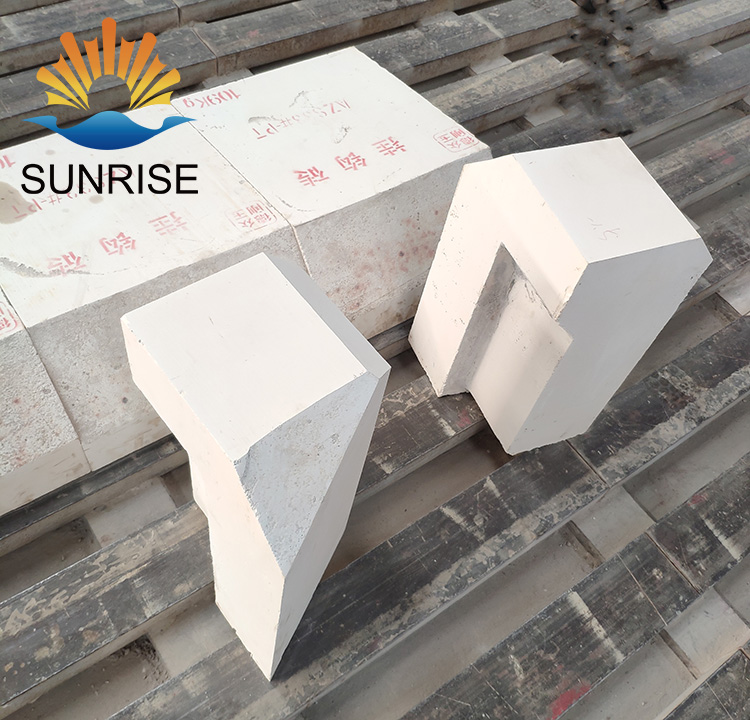

The fused refractory material is made by melting the precisely prepared mixture in an electric arc furnace, and then casting it in a sand mold. The ingot is heat-treated and then machined. After smelting, complete coarse crystals and dense structures can be obtained. Compared with sintered refractory materials, it has the characteristics of compact structure, very low porosity, large bulk density, high mechanical strength and high temperature structure strength, and strong resistance to liquid glass erosion. The important indexes for evaluating the performance of fused refractory materials are: chemical and crystal phase composition, bulk density, glass phase out temperature, glass phase exudation volume and foaming rate. The meaning of foaming is that when 02 diffuses into the brick, it reacts with the gases such as SO2 and N2 released from the carbon or carbides, sulfides and nitrides. These gases squeeze the molten phase out of the brick and form visible bubbles on the surface. . The main varieties currently produced are: fused mullite brick, fused zirconium corundum brick, fused chrome zirconium corundum brick, fused quartz brick, fused corundum brick and so on.

Fused refractory is an artificial rock. Its manufacturing method includes reduction method and oxidation method.

The reduction method is to put the selected and pretreated raw materials into an electric furnace, use graphite electrodes to melt them, and cast them into a model after a certain period of time. The melting temperature is about 2000 degrees Celsius. In this method, since the graphite electrode is directly inserted into the molten liquid, the solution is carburized. Moreover, its working space is in a reducing atmosphere, so that iron and titanium oxide impurities in the batch are reduced to low-priced oxides, and the precipitation temperature of the glass phase is reduced.

The oxidative melting method is to melt a batch of a predetermined composition in an electric arc furnace, using a long arc, and the electrodes are not in contact with the melt, so carbon does not penetrate into the melt, and the working space is in an oxidizing atmosphere. The fused refractory produced by this method has a low carbon content and a glass phase precipitation temperature that is more than 100C higher than the reduction method, which greatly improves the performance. It is now commonly produced by the oxidative melting method.